Hello all,

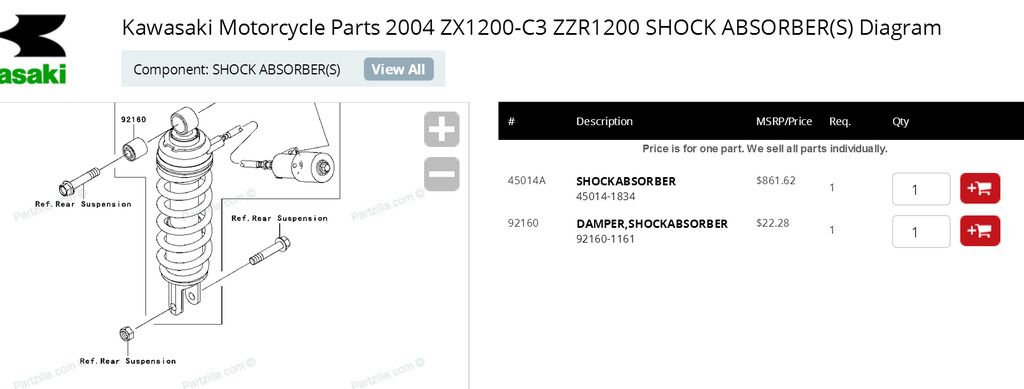

I just purchased a C14 rear shock and I was looking for some info on what modifications I need to do to install it.

I haven't been following the site for a while and see it has changed allot from last fall. (when I purchased a boat with no motor that had been my focus till now)

I did a search on the forums and can't find any of the information on what people have done to install a C14 shock on a C10.

I also have a lowering link to install with it.

If anyone could give me a heads up on what I might need for different hardware or anything I will need to modify that would be great. (or how or where I could do a search to find it)

Thanks

Joe C

I just purchased a C14 rear shock and I was looking for some info on what modifications I need to do to install it.

I haven't been following the site for a while and see it has changed allot from last fall. (when I purchased a boat with no motor that had been my focus till now)

I did a search on the forums and can't find any of the information on what people have done to install a C14 shock on a C10.

I also have a lowering link to install with it.

If anyone could give me a heads up on what I might need for different hardware or anything I will need to modify that would be great. (or how or where I could do a search to find it)

Thanks

Joe C