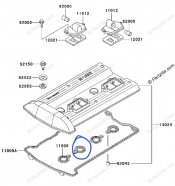

Not a problem. That’s the way to go. Went the same with mine. Makes valves adjustment so much easier.Thanks for the offer! I almost bought a set, but then I poked around on eBay and found a cover from a bike sold overseas without the PAIR. I think it was off a GPZ900, but it's the same cover as our bikes. Just gotta get it cleaned up.View attachment 37622

/cloudfront-us-east-1.images.arcpublishing.com/octane/47MMGMNR4KVWZVL2J3VYTN7DQM.jpg)