Ok - Committing to start changing / balancing my own tires. Lots of information on the site.

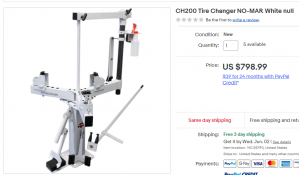

Possibly a tire changer in the future, unless I can be convinced otherwise, I would like to start with the best manual tools.

While an actual tire changer (may be that is best) what is a list of the ‘made for the job’ tools I need to change my tires myself?

One note: Prefer to avoid buying Kawasaki over-priced tools if possible.

Will provide my review for others considering changing own tires. Dealership prices too high when changing tires 3+ times a season...

Possibly a tire changer in the future, unless I can be convinced otherwise, I would like to start with the best manual tools.

While an actual tire changer (may be that is best) what is a list of the ‘made for the job’ tools I need to change my tires myself?

One note: Prefer to avoid buying Kawasaki over-priced tools if possible.

Will provide my review for others considering changing own tires. Dealership prices too high when changing tires 3+ times a season...