-

WOULD YOU LIKE TO BE ABLE TO POST? REGISTER FOR COG MEMBERSHIP

All registration must be done through the club's main webpage: To register / join COG, click here

For instructions to convert to full membership, click here

-

Can't post after logging to the forum for the first time... Try Again - If you can't post in the forum, sign out of both the membership site and the forum and log in again. Make sure your COG membership is active and your browser allow cookies. If you still can't post, contact the COG IT guy at IT@Concours.org.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt Torque Settings ??

- Thread starter tware

- Start date

Fred_Harmon_TX said:Another thing that can impact vibration levels is a throttle body sync.

Just curious Fred, what do you base that on? Some have said they're TB sync had no effect, while others indicated it did. Are you going by the ones that did, or do you have some 'inside' information I missed?

C1xRider said:Fred_Harmon_TX said:Another thing that can impact vibration levels is a throttle body sync.

Just curious Fred, what do you base that on? Some have said they're TB sync had no effect, while others indicated it did. Are you going by the ones that did, or do you have some 'inside' information I missed?

I did it to mine and it helped.

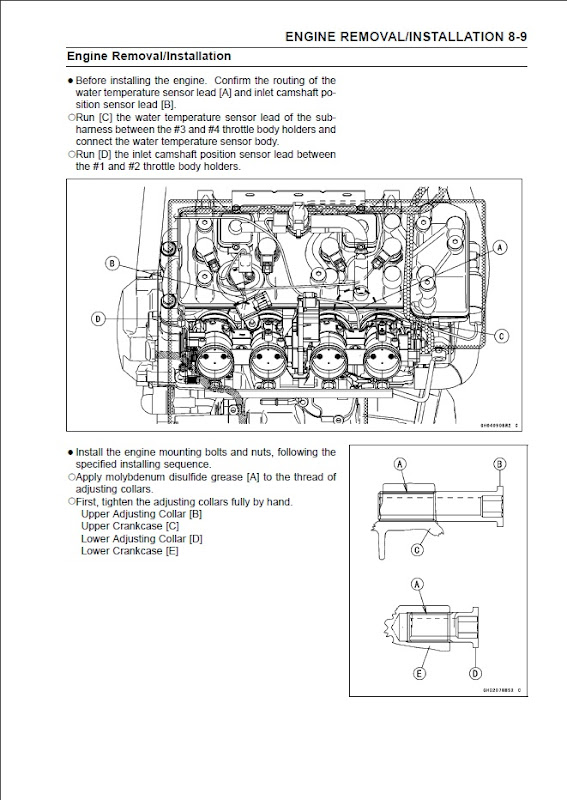

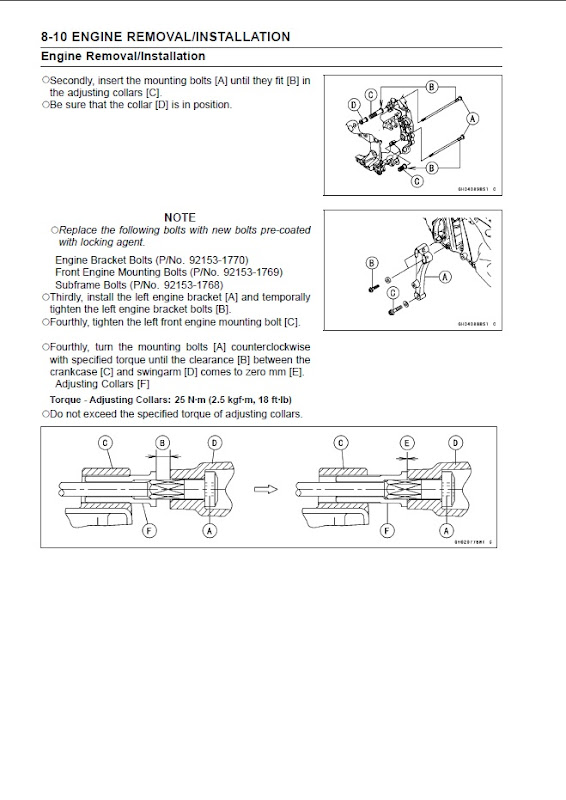

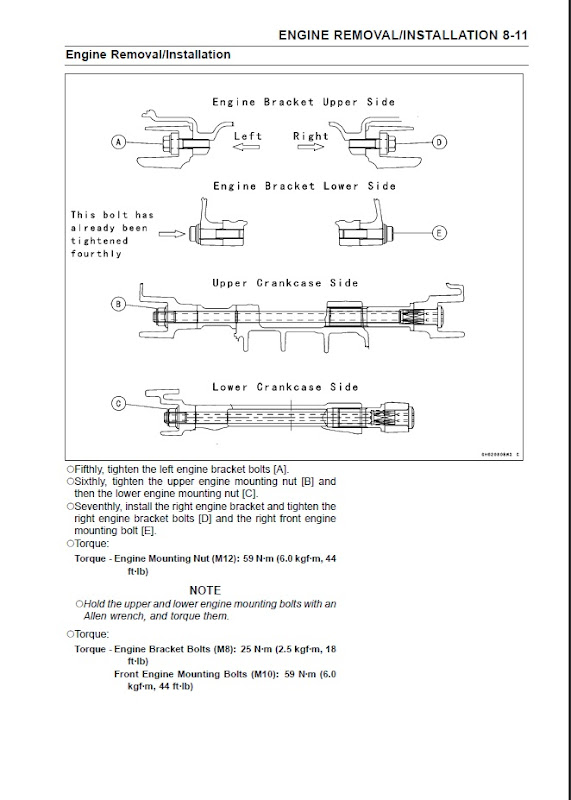

The two top bolts engine mount bolts really affect vibration if not properly torqued. 18 ft. lbs. Mine were way over torqued from the factory. They still get loose, even with blue locktite. But then again I have one of the buzzy C-14's.

Like it or not, over torqued bolts in general are thrown away because you can't see it but they've been stretched and are no good. They will LOOSEN! Bolts used in high vibration applications are either time-life or are originally over spec for CTOA and therefore over torqued at assembly. If Kawasaki said you had to buy and install new motor mounts and bolts every 500 hours you would scream.

Likewise, engine case bolts, cylinder head bolts and studs and wing strut... oops! I was thinking about airplanes! So, what's the difference? The difference is the airplane has to fly so, 20% bigger than necessary everything under the sun isn't called for in their design. They just use better and more expensive smaller bits and pieces... that don't get over torqued.

Likewise, engine case bolts, cylinder head bolts and studs and wing strut... oops! I was thinking about airplanes! So, what's the difference? The difference is the airplane has to fly so, 20% bigger than necessary everything under the sun isn't called for in their design. They just use better and more expensive smaller bits and pieces... that don't get over torqued.

I re-re-torqued all the engine mount bolts on mine again this morning. The two upper bracket mount bolts in the recess on each side took a lot more effort to break loose than the two to the rear of them. I was getting concerned that the right side one was knurling the threads. I would not have expected them to get tighter, so maybe the thread locker stuff was causing more friction? The rear two were still fine.

The two adjusting collars seemed to be a little bound up when I tried to loosen them (the nuts were loose and I had a jack under the motor). Once they started moving a little better, I could not get my beam torque wrench to give me any confidence in an accurate reading at 11 ft lbs, so I "tightened" them until I just felt the tightening resistance change (after making sure that point was actually them getting tight) , and then torqued the nuts to 44 ft lbs.

I didn't notice any real change in buzzyness during the ride in to work, though it may have been a little less in the 3500 area. I did notice there was much more vibs going down hill under full compression braking in 4th gear at 2500RPM then I get on the flats or when I go up that hill in 4th gear at the same RPM.

The two adjusting collars seemed to be a little bound up when I tried to loosen them (the nuts were loose and I had a jack under the motor). Once they started moving a little better, I could not get my beam torque wrench to give me any confidence in an accurate reading at 11 ft lbs, so I "tightened" them until I just felt the tightening resistance change (after making sure that point was actually them getting tight) , and then torqued the nuts to 44 ft lbs.

I didn't notice any real change in buzzyness during the ride in to work, though it may have been a little less in the 3500 area. I did notice there was much more vibs going down hill under full compression braking in 4th gear at 2500RPM then I get on the flats or when I go up that hill in 4th gear at the same RPM.