So I know the fuel gauge is notoriously bad on these bikes, but when my fuel gauge is on empty I only fuel 3.25-4 gallons. Don't these things have a 7.4 gallon gas tank? Is this one too bad to mod or is the 7.4 fuel tank on the c14?

-

WOULD YOU LIKE TO BE ABLE TO POST? REGISTER FOR COG MEMBERSHIP

All registration must be done through the club's main webpage: To register / join COG, click here

For instructions to convert to full membership, click here

-

Can't post after logging to the forum for the first time... Try Again - If you can't post in the forum, sign out of both the membership site and the forum and log in again. Make sure your COG membership is active and your browser allow cookies. If you still can't post, contact the COG IT guy at IT@Concours.org.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

C10 fuel gauge

- Thread starter nomoreusmc6802

- Start date

There's pessimistic, and there's being off by HALF! LoL

How many miles out of a tank on a c10?

All depends on how u ride it of course. When I had my 98, I could go 250 miles to the tank on my 25 mile to work commute.

One of the c10 thread discussed bending the float are if I remember correctly..

One of the c10 thread discussed bending the float are if I remember correctly..

Works well .I thought Harry had worked a resistor to put on the circuit to get it a lot closer to being right?

I thought Harry had worked a resistor to put on the circuit to get it a lot closer to being right?

Somebody did, and I thought the "magic" value was 220 Ohms, or there about.

I put in a 10 turn variable resistor in parallel with the sender leads (didn't document the value

The black magic of electricity is the main reason I got a civil engineering degree…

I only had 2 - 100 ohm resistors in my very small electronics bag of tricks. I wired them in parallel (for 200 ohms) into the sending unit plug. It did change the reading of the gauge, but made it too optimistic. I had to go to reserve before the needle got near the red area of the gauge. I guess that 20 ohms makes the difference.

I’ve put about 1200 miles on my C10 now. I consistently get 38-39 mpg. That’s pretty much staying under 4000 rpm and trying to go easy on acceleration. Still enjoying the ride!!

I only had 2 - 100 ohm resistors in my very small electronics bag of tricks. I wired them in parallel (for 200 ohms) into the sending unit plug. It did change the reading of the gauge, but made it too optimistic. I had to go to reserve before the needle got near the red area of the gauge. I guess that 20 ohms makes the difference.

I’ve put about 1200 miles on my C10 now. I consistently get 38-39 mpg. That’s pretty much staying under 4000 rpm and trying to go easy on acceleration. Still enjoying the ride!!

Or should I have wired them in series for 200 ohms?

civil engineering degree…

You didnt have to take basic AC/DC circuits?

4 Ways to Calculate Series and Parallel Resistance - wikiHow

Need to know how to calculate series resistance, parallel resistance, and a combined series and parallel network? If you don't want to fry your circuit board, you do! This article will show you how in just a few easy steps. Before reading...

www.wikihow.com

www.wikihow.com

Attached is my guide for bending the fuel gauge sender arm that I developed in 1998 for C-10 #1. Bending the arm so it conforms to line #3 will allow the fuel gauge to just be hitting the red reserve mark when you will have to switch the petcock to reserve. I'm on C-10 #4 and this graph has allowed me to adjust the arm exactly where it needs to be on all my subsequent C-10s without trial and error.

Or should I have wired them in series for 200 ohms?

Yes you should have wired them in series

I use a 220 ohm resistor and it corrected things perfectly.

I hit reserve between 235 - 250 miles while yielding 41-44 mpg.

At that point the needle is just left of the 'E' white hash and touching the red.

That leaves me with about a gallon and a half (~60 miles) before absolutely empty.

I hit reserve between 235 - 250 miles while yielding 41-44 mpg.

At that point the needle is just left of the 'E' white hash and touching the red.

That leaves me with about a gallon and a half (~60 miles) before absolutely empty.

Last edited:

Murph - I did have to take the basic circuit theory class in lower division - 3 times before I finally passed the course! It was all theory with no lab - we never actually touched a circuit element - resistor/capacitor/inductors, etc, never used a VOM, never built a circuit with a breadboard, etc. It was all the theoretical math. Besides, I started as a pre-computer draftsman for a civil engineer in 1980 because I could visualize in 3D making topographic maps manually. In my old age I have studied some of YouTube stuff on simple circuits for M/C and automotive applications. But apparently not enough to realize I should have put my resistors in series!!

2 - 100 ohm resistors in parallel would wind up being 50 ohms. Yes, in series you would get 200 ohms.The black magic of electricity is the main reason I got a civil engineering degree…

I only had 2 - 100 ohm resistors in my very small electronics bag of tricks. I wired them in parallel (for 200 ohms) into the sending unit plug. It did change the reading of the gauge, but made it too optimistic. I had to go to reserve before the needle got near the red area of the gauge. I guess that 20 ohms makes the difference.

I’ve put about 1200 miles on my C10 now. I consistently get 38-39 mpg. That’s pretty much staying under 4000 rpm and trying to go easy on acceleration. Still enjoying the ride!!

I'm late the thread... here's my $0.02

The fuel gauge meter in the design is probably an off the shelf device. Since most connies are consistently off I feel any error in the gauge deflection is due to the sender unit mechanics or electronics not being matched well to the meter.

Modifying the mechanics of the sender (bending the arm) is an option, but it's a heck of a lot easier to dial in a good setting electronically Adding a resistor across the sender changes the effective resistance of the sending, and hence the meter deflection.

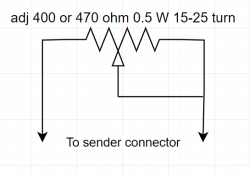

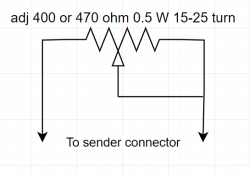

An enterprising individual might consider using a 400 (or 470) ohm multi-turn trimmer potentiometer instead of a fixed 220 ohm resistor - similar to this one: 3296W-1-471LF. If using a pot, adjust prior to connection to 220 ohm using an ohmmeter - then you can dial in the setting almost perfectly after install.

The fuel gauge meter in the design is probably an off the shelf device. Since most connies are consistently off I feel any error in the gauge deflection is due to the sender unit mechanics or electronics not being matched well to the meter.

Modifying the mechanics of the sender (bending the arm) is an option, but it's a heck of a lot easier to dial in a good setting electronically Adding a resistor across the sender changes the effective resistance of the sending, and hence the meter deflection.

An enterprising individual might consider using a 400 (or 470) ohm multi-turn trimmer potentiometer instead of a fixed 220 ohm resistor - similar to this one: 3296W-1-471LF. If using a pot, adjust prior to connection to 220 ohm using an ohmmeter - then you can dial in the setting almost perfectly after install.

I'm late the thread... here's my $0.02

The fuel gauge meter in the design is probably an off the shelf device. Since most connies are consistently off I feel any error in the gauge deflection is due to the sender unit mechanics or electronics not being matched well to the meter.

Modifying the mechanics of the sender (bending the arm) is an option, but it's a heck of a lot easier to dial in a good setting electronically Adding a resistor across the sender changes the effective resistance of the sending, and hence the meter deflection.

An enterprising individual might consider using a 400 (or 470) ohm multi-turn trimmer potentiometer instead of a fixed 220 ohm resistor - similar to this one: 3296W-1-471LF. If using a pot, adjust prior to connection to 220 ohm using an ohmmeter - then you can dial in the setting almost perfectly after install.

View attachment 36291

Yup - that's what I did.

'"I'm late the thread... here's my $0.02

The fuel gauge meter in the design is probably an off the shelf device. Since most connies are consistently off I feel any error in the gauge deflection is due to the sender unit mechanics or electronics not being matched well to the meter.

Modifying the mechanics of the sender (bending the arm) is an option, but it's a heck of a lot easier to dial in a good setting electronically Adding a resistor across the sender changes the effective resistance of the sending, and hence the meter deflection.

An enterprising individual might consider using a 400 (or 470) ohm multi-turn trimmer potentiometer instead of a fixed 220 ohm resistor - similar to this one: 3296W-1-471LF. If using a pot, adjust prior to connection to 220 ohm using an ohmmeter - then you can dial in the setting almost perfectly after install.

View attachment 36291

Why would a "frugal Cogger" want to spend money on resistors or a potentiometer when there is a FREE FIX available?

Cuz there's Coggers that will send you a resistor for free.Why would a "frugal Cogger" want to spend money on resistors or a potentiometer when there is a FREE FIX available?

Frugality has many forms. Money, time, effort, etc. it’s pretty easy to fish out the fuel sending unit plug from under the tank without removing the fuel tank, draining down the tank, or removing its sending unit. Splicing a resistor or group of resistors into one end the plug is also pretty easy. One just has to have a basic understanding of simple circuitry…

I emptied the tank, filled, the number of liters that corresponds to the reserve and I adjusted my adjustable resistance, motorcycle right, of course.I'm late the thread... here's my $0.02

The fuel gauge meter in the design is probably an off the shelf device. Since most connies are consistently off I feel any error in the gauge deflection is due to the sender unit mechanics or electronics not being matched well to the meter.

Modifying the mechanics of the sender (bending the arm) is an option, but it's a heck of a lot easier to dial in a good setting electronically Adding a resistor across the sender changes the effective resistance of the sending, and hence the meter deflection.

An enterprising individual might consider using a 400 (or 470) ohm multi-turn trimmer potentiometer instead of a fixed 220 ohm resistor - similar to this one: 3296W-1-471LF. If using a pot, adjust prior to connection to 220 ohm using an ohmmeter - then you can dial in the setting almost perfectly after install.

View attachment 36291

Really? Who are these Coggers and how do I get one?Cuz there's Coggers that will send you a resistor for free.

PM me with your address and I will send you one.Really? Who are these Coggers and how do I get one?