Well, I really did it this time. Got tired or hearing the cam chain rattle and purchased the APE manual adjuster. After reading so much about not overtightening the adjuster, I under tightened by a lot. When I hit the starter button, I heard it rattling and a sound like it was skipping so I stopped. I aligned the 1.4 T Mark to the index mark at the crank and pulled the valve cover off to find the cam sprockets appear to be 180 degrees off.

Scenario 1 - maybe the chain did not skip

I find it odd that I could have skipped it perfectly 180 degrees. Might I just need to rotate the 1.4 mark 180 degrees and see where I stand? My Clymer manual does not discuss it specifically but I see that in order the check the alignment after a cam installation, it says to rotate the crank two full turns.

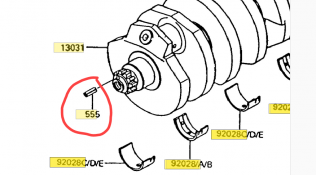

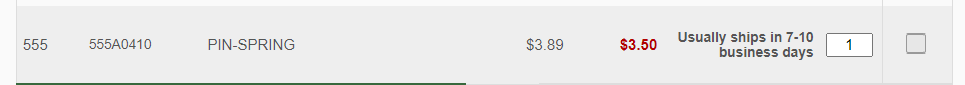

Scenario 2 - chain skipped on the lower timing sprocket

It seems plausible that the chain could skip on the lower timing gear but not on the cam gears due to the upper cam chain guide. If that is the case, what is the fix?

Scenario 3 - chain skipped on the cam gear sprockets

Will this procedure work?

* Loosen valve adjustments from rocker

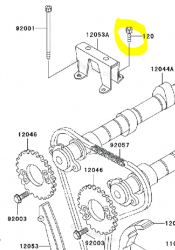

* Remove upper cam chain guide

* Remove cam chain tensioner

* Pick chain up enough to rotate cam into alignment?

See attached pictures.

Paul

Scenario 1 - maybe the chain did not skip

I find it odd that I could have skipped it perfectly 180 degrees. Might I just need to rotate the 1.4 mark 180 degrees and see where I stand? My Clymer manual does not discuss it specifically but I see that in order the check the alignment after a cam installation, it says to rotate the crank two full turns.

Scenario 2 - chain skipped on the lower timing sprocket

It seems plausible that the chain could skip on the lower timing gear but not on the cam gears due to the upper cam chain guide. If that is the case, what is the fix?

Scenario 3 - chain skipped on the cam gear sprockets

Will this procedure work?

* Loosen valve adjustments from rocker

* Remove upper cam chain guide

* Remove cam chain tensioner

* Pick chain up enough to rotate cam into alignment?

See attached pictures.

Paul

Attachments

Last edited: