-

WOULD YOU LIKE TO BE ABLE TO POST? REGISTER FOR COG MEMBERSHIP

All registration must be done through the club's main webpage: To register / join COG, click here

For instructions to convert to full membership, click here

-

Can't post after logging to the forum for the first time... Try Again - If you can't post in the forum, sign out of both the membership site and the forum and log in again. Make sure your COG membership is active and your browser allow cookies. If you still can't post, contact the COG IT guy at IT@Concours.org.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First valve adjustment

- Thread starter tjnoma99

- Start date

You need a valve cover gasket, not a head gasket. I've read some on here say they used the same valve cover gasket for 100k mi or better, so you may or may not need one. Get the spark plug well gaskets. You might also want to take a look at the rubber pieces that go on the bolts that hold down the valve cover. Fresh ones will put more pressure on the valve cover and possibly help to prevent leakage at the gasket. As far as the block off plates, the opinions are split. I'd say do whatever makes you feel good, it's not a big deal.

jb_cb900

Street Cruiser

You can do the valve adjustment without removing the pickup coil cover so you won't need that gasket. Just use the timing marks on the cams or have the lobes pointing up. With the plugs out, you can spin the engine with the trans in 6th using the rear wheel or just bump the starter. If you haven't found it already in the Tech Pages, here's the link for valve adjustment:

http://www.cog-online.org/clubportal/clubstatic.cfm?clubID=1328&pubmenuoptID=29654

When putting it back together, be gentle on the valve cover bolts: 87 in/lb

http://www.cog-online.org/clubportal/clubstatic.cfm?clubID=1328&pubmenuoptID=29654

When putting it back together, be gentle on the valve cover bolts: 87 in/lb

Yes you can do a valve adj and reuse the old cam cover gasket.

BUT if the old gasket is damaged you will be waiting for Murph's

to send you a new one. When putting the cam cover back on be

sure the gasket is seated on the front side of the head. This is

where it usually gets pinched. You will not know this till after

you put everything back together.

BUT if the old gasket is damaged you will be waiting for Murph's

to send you a new one. When putting the cam cover back on be

sure the gasket is seated on the front side of the head. This is

where it usually gets pinched. You will not know this till after

you put everything back together.

I've done two valve jobs now, and the second one was way easier with some experience.

I would highly suggest going ahead and replacing the t-stat, oring, and rear coolant long rings while you're in there. Not only is it good preventive maintenance, getting the cover back on is a breeze.

I use indian head on the cover side. Apply, wait a bit to let it cure, then put the gasket on and let it sit 24 hours. If you have the tstat and coolant log off, you can approach from behind. Like many have said, just a little RTV in the half moon wells, and a little on the corners. I went sparingly on that part as well. First attempt at mounting the cover was successful. Much better than the 3 times it took on my 06 to get a good seal without a leak. I hadn't taken the tstat off on that guy, so it's not a surprise.

I would highly suggest going ahead and replacing the t-stat, oring, and rear coolant long rings while you're in there. Not only is it good preventive maintenance, getting the cover back on is a breeze.

I use indian head on the cover side. Apply, wait a bit to let it cure, then put the gasket on and let it sit 24 hours. If you have the tstat and coolant log off, you can approach from behind. Like many have said, just a little RTV in the half moon wells, and a little on the corners. I went sparingly on that part as well. First attempt at mounting the cover was successful. Much better than the 3 times it took on my 06 to get a good seal without a leak. I hadn't taken the tstat off on that guy, so it's not a surprise.

As Bud stated, new spark plug well gaskets for sure. A slow leak there isn't good to find out while out on the road. I had to use a new cam cover gasket on my first valve adjustment because it had some cracks in it (it was probably the original) but the last time it was good to re-use. I have a spare I keep on hand just in case.

Just use the starter to bump it, don't use manual's instructions to turn it over with the nut under the side cover.

Just use the starter to bump it, don't use manual's instructions to turn it over with the nut under the side cover.

Mettler1

Sport Tourer

Bob_C_CT said:As Bud stated, new spark plug well gaskets for sure. A slow leak there isn't good to find out while out on the road. I had to use a new cam cover gasket on my first valve adjustment because it had some cracks in it (it was probably the original) but the last time it was good to re-use. I have a spare I keep on hand just in case.

Just use the starter to bump it, don't use manual's instructions to turn it over with the nut under the side cover.

Exactly! I always use new spark plug well gaskets when I do valve adjustments and have a valve cover gasket on hand just in case.

Get my gaskets from Murphs' !! They ship FAST!!

https://www.murphskits.com/index.php?cPath=1_105&sort=2a&page=2

Mettler1 said:Get my gaskets from Murphs' !! They ship FAST!!

Brought to you by Carl's Junior eh?

Here is a detailed guide to a Kawasaki Concours valve adjustment. I found these instructions using a Google search "Kawasaki Concours valve adjustment". I printed these instructions out and then marked up the printout with comments for the next valve adjustment.

http://www.delp.net/Concours/Tech/Microfiche/Valves/index.htm

I suggest a roll of red tape and blue tape for color coding the three smaller fuel tank vent hoses you will see when you remove the motorcycle seat. The little wire hose clamps will slide down the vent hoses and disappear in the darkness. The ring of red tape or blue tape will stop the wire hose clamps from dropping out of sight. On my bike, there is a red dot on the tank that matches a red tape on a vent hose. There is also a blue marked hose.

I suggest a shallow cardboard box to set the gas tank on. You don't want to ding the paint or boing the fuel valve. If you can avoid it, don't rotate the "reserve prime run" fuel valve. My California experience with anti-smog gasoline ingredients and ethanol is don't fiddle with the fuel valve if you can avoid it.

My other California experience with the gas tank vent and vapor recovery plumbing is if your bike is stock (ie. not modified already with "blocker kits" and other defeat arrangements) the best thing is to be patient and get the hoses hooked up right.

The C10 engine uses a lifter that uses one cam lobe and a Y-shaped rocker arm that opens two valves. The interesting and tricky part is getting both adjuster screws on the Y shaped rocker arm set to exactly the same clearance. I am probably going to buy some go-no-go stepped feeler gauges for the next adjustment. Best wishes that you have an interesting time getting into the Kawasaki engine.

http://www.delp.net/Concours/Tech/Microfiche/Valves/index.htm

I suggest a roll of red tape and blue tape for color coding the three smaller fuel tank vent hoses you will see when you remove the motorcycle seat. The little wire hose clamps will slide down the vent hoses and disappear in the darkness. The ring of red tape or blue tape will stop the wire hose clamps from dropping out of sight. On my bike, there is a red dot on the tank that matches a red tape on a vent hose. There is also a blue marked hose.

I suggest a shallow cardboard box to set the gas tank on. You don't want to ding the paint or boing the fuel valve. If you can avoid it, don't rotate the "reserve prime run" fuel valve. My California experience with anti-smog gasoline ingredients and ethanol is don't fiddle with the fuel valve if you can avoid it.

My other California experience with the gas tank vent and vapor recovery plumbing is if your bike is stock (ie. not modified already with "blocker kits" and other defeat arrangements) the best thing is to be patient and get the hoses hooked up right.

The C10 engine uses a lifter that uses one cam lobe and a Y-shaped rocker arm that opens two valves. The interesting and tricky part is getting both adjuster screws on the Y shaped rocker arm set to exactly the same clearance. I am probably going to buy some go-no-go stepped feeler gauges for the next adjustment. Best wishes that you have an interesting time getting into the Kawasaki engine.

No need to remove pulse cover, bump engine with starter or as others have done put tranny in 6 th gear and then use rear tire to move motor.

The crankshaft nut under the pulse cover is pinned and if you don't have all the spark plugs out you will possibly break pin and end up with a bigger job. And one less gasket to have on hand.

The crankshaft nut under the pulse cover is pinned and if you don't have all the spark plugs out you will possibly break pin and end up with a bigger job. And one less gasket to have on hand.

Bob_C_CT said:No need to remove pulse cover, bump engine with starter or as others have done put tranny in 6 th gear and then use rear tire to move motor.

The crankshaft nut under the pulse cover is pinned and if you don't have all the spark plugs out you will possibly break pin and end up with a bigger job. And one less gasket to have on hand.

Just as a reminder, and also to warn new folks, you can't upshift the transmission to 6th gear unless the engine is running, and transmission is spinning in gear, due to the neutral detent lockout feature... so if you want it in 6th, it requires having the bike on the centerstand, running, and carefully shift upwards to get it into 6th... then, stop the engine... just be careful and don't rock it off the stand....during the attempt. :great:

All of the Kawasaki bikes I have owned I have been able to up shift from neutral to high gear with the bike stopped. The PNF makes it so you don't bypass neutral from first when you are stopped. You will go from first to second when in motion. Once you are in neutral you will shift one gear for each movement of the lever. You will have to rock the bike fwd and back on the wheels or rotate the rear wheel on the center stand if the gear teeth hit point to point on the next gear. If they are lined up point to valley it will go right in. Just don't force it. I like the idea of doing it by hand with the bike on the center stand.

DO NOT RUN THE BIKE IN GEAR ON THE CENTER STAND.

As you go up in gears the wheel will be flying and any imbalance will cause it to bounce. Just shutting it off at speed could cause it to come off the center stand.

DO NOT RUN THE BIKE IN GEAR ON THE CENTER STAND.

As you go up in gears the wheel will be flying and any imbalance will cause it to bounce. Just shutting it off at speed could cause it to come off the center stand.

WillyP said:Works for me too. Maybe our neutral lockout is broken?

I think its working as designed. I think if you have force on the rear wheel, it considers that an override of the neutral finder. If you werent turning the wheel, it wouldnt go anywhere....

JPD said:All of the Kawasaki bikes I have owned I have been able to up shift from neutral to high gear with the bike stopped. The PNF makes it so you don't bypass neutral from first when you are stopped. You will go from first to second when in motion. Once you are in neutral you will shift one gear for each movement of the lever. You will have to rock the bike fwd and back on the wheels or rotate the rear wheel on the center stand if the gear teeth hit point to point on the next gear. If they are lined up point to valley it will go right in. Just don't force it. I like the idea of doing it by hand with the bike on the center stand.

DO NOT RUN THE BIKE IN GEAR ON THE CENTER STAND.

As you go up in gears the wheel will be flying and any imbalance will cause it to bounce. Just shutting it off at speed could cause it to come off the center stand.

So I have 4 people telling me I'm wrong. :-[ :-X

Every Kaw I have owned, with exception to my old motocross bike, has/had the centrfically designed 3 ball lockout system located in the transmission output shaft, and an outer gear (5th), designed to prevent upshifting from neutral by the movement of 2 shifting forks together, one of which releasing that "locked gear", and one moving a different gear into position of mating, unless the output shaft is spinning. I have never been able to spin the tire by hand, fast enough to actuate them to allow an upshift with the bike not running, even with plugs out, clutch pulled in, and spinning as fast as I can by hand...

The Concours also has a "neutral finder" on the star end of the shift drum, which does locate neutral also and gives the tactile feel telling you it truely is in neutral.. but if you can shift the gears upwards, without the transmission output shaft spinning... the positive lockout, the one internal, is not functioning correctly.

FSM section on transmission, 8-20. Dealing with output shaft, 5th gear, and the balls that prevent upshifts.... :

I have defeated that feature in the past by spinning the clutch basket hub with plates removed, using a rubber snading pad chufked in a drill, to spin it up fast enough to defeat the lockout balls when srvicing and repairing older KZ models during tranny repairs, to insure they were functioning prior to buttoning up the engine, but that's a bit labor intensive just to get the bike up to top gear.

I guess I should have said "with the bike on centerstand....etc., ....then carefully slow and stop the rear wheel with the brake, and shut off motor..."

But assume anyone doing this would be using fommon sense, and extreme cautionary techniques... sorry for suggesting something dangerous.

Carry on... didn't mean to highjack the thread over this. :truce:

Jim said:It's not a matter of speed. Just roll the wheel slowly forward while pulling up on the shift lever.

Whatever...

Read about it in section 8-20 FSM.

Did you buy your bike new, and never had transmission work done on it?

Roll the wheel slowly, while pulling the shifter upwards... ok, where does the third hand come from to disengage the clutch while doing this, so you are not trying to turn the engine over during this operation.....?????

Sorry... but splain it all to me again.... :-[

jb_cb900

Street Cruiser

No, I'm not. I just turn the rear wheel and pull up to go into 2nd. Then, turn the wheel until it stops when the slack is gone from the drive and pull up again. Cams never move during this operation. I've got to bump it much harder to get the cams moving. Works like charm for me. I didn't buy my bike new but it certainly hasn't exhibited any problems with the trans in the 50K miles I've put on it. Goes into neutral without problem so I don't suspect it had transmission problems. Anyway, let's all do whatever works for us and call it good. :beerchug:

Well... you have a special bike.

I am making statements based on disassembly, and servicing I have done.

I am also basing this on mechanical facts about this transmission, that when operating correctly, "bumping" the thing still should not disengage fifth gear, from its locked in position, providing the shift interlock I speak of..... and the output shaft must be rotating at a speed capacity to throw the 3 locking balls outward... and that means "spinning", to do so. If it works on your bike... that's fine. I say it should not work.

I only wish I could post the diagrams showing the progression of shift fork actuation, on each gearset involved, at various stages of operation. They are locked in photobucket...

Won't matter anyway, because it only shows How the correctly working assembly.prevents movement... I can't explain why yours does what it does, other than missing balls in the 5th gear output section, or some other such thing... and it really has little to do with 5th gear per se, but that the progression utilizes multiple gears in mesh, to lock out other gears, and movements thereafter...

Again, I don't mean to be inflammatory, but I'm saying what your bike is doing, is not a representation of how they are supposed to work, or what I have been exposed to, and seen, and worked on, in the last 42 years of owning and working on kawasaki motorcycles.

Your bike is special... :great: :beerchug: :beerchug:

I am making statements based on disassembly, and servicing I have done.

I am also basing this on mechanical facts about this transmission, that when operating correctly, "bumping" the thing still should not disengage fifth gear, from its locked in position, providing the shift interlock I speak of..... and the output shaft must be rotating at a speed capacity to throw the 3 locking balls outward... and that means "spinning", to do so. If it works on your bike... that's fine. I say it should not work.

I only wish I could post the diagrams showing the progression of shift fork actuation, on each gearset involved, at various stages of operation. They are locked in photobucket...

Won't matter anyway, because it only shows How the correctly working assembly.prevents movement... I can't explain why yours does what it does, other than missing balls in the 5th gear output section, or some other such thing... and it really has little to do with 5th gear per se, but that the progression utilizes multiple gears in mesh, to lock out other gears, and movements thereafter...

Again, I don't mean to be inflammatory, but I'm saying what your bike is doing, is not a representation of how they are supposed to work, or what I have been exposed to, and seen, and worked on, in the last 42 years of owning and working on kawasaki motorcycles.

Your bike is special... :great: :beerchug: :beerchug:

Jim said:Neutral to 2nd, roll tire slowly and pull up on shift lever. 2nd to 3rd, roll tire forward until it bumps from taking up all the drive-line slack. Not too hard, just a good bump and pull up on the shift lever again. Repeat....

Yes, this can be done. I didn't believe it myself until Ken **** showed me how to do it. Not once but many times. It is just a matter of technique. But that didn't keep me from removing the pesky automatic neutral finder when I had the transmission out for another project:

With perfect results I might add.

Dan

Well, I never differ with MOB, but......but.....ummmm, yeah, on my bike I can shift through the range normally by slowly bumping the rear wheel by hand, without the engine running or crankshaft turning, it somehow defeats the Automatic Neutral Hider. I have SISF's "7th gear" mod, but otherwise nothing done in the engine/trans that would affect it.

But for valve lash adjustments, I just use the starter bump method with the plugs out.

But for valve lash adjustments, I just use the starter bump method with the plugs out.

Bergmen said:Jim said:Neutral to 2nd, roll tire slowly and pull up on shift lever. 2nd to 3rd, roll tire forward until it bumps from taking up all the drive-line slack. Not too hard, just a good bump and pull up on the shift lever again. Repeat....

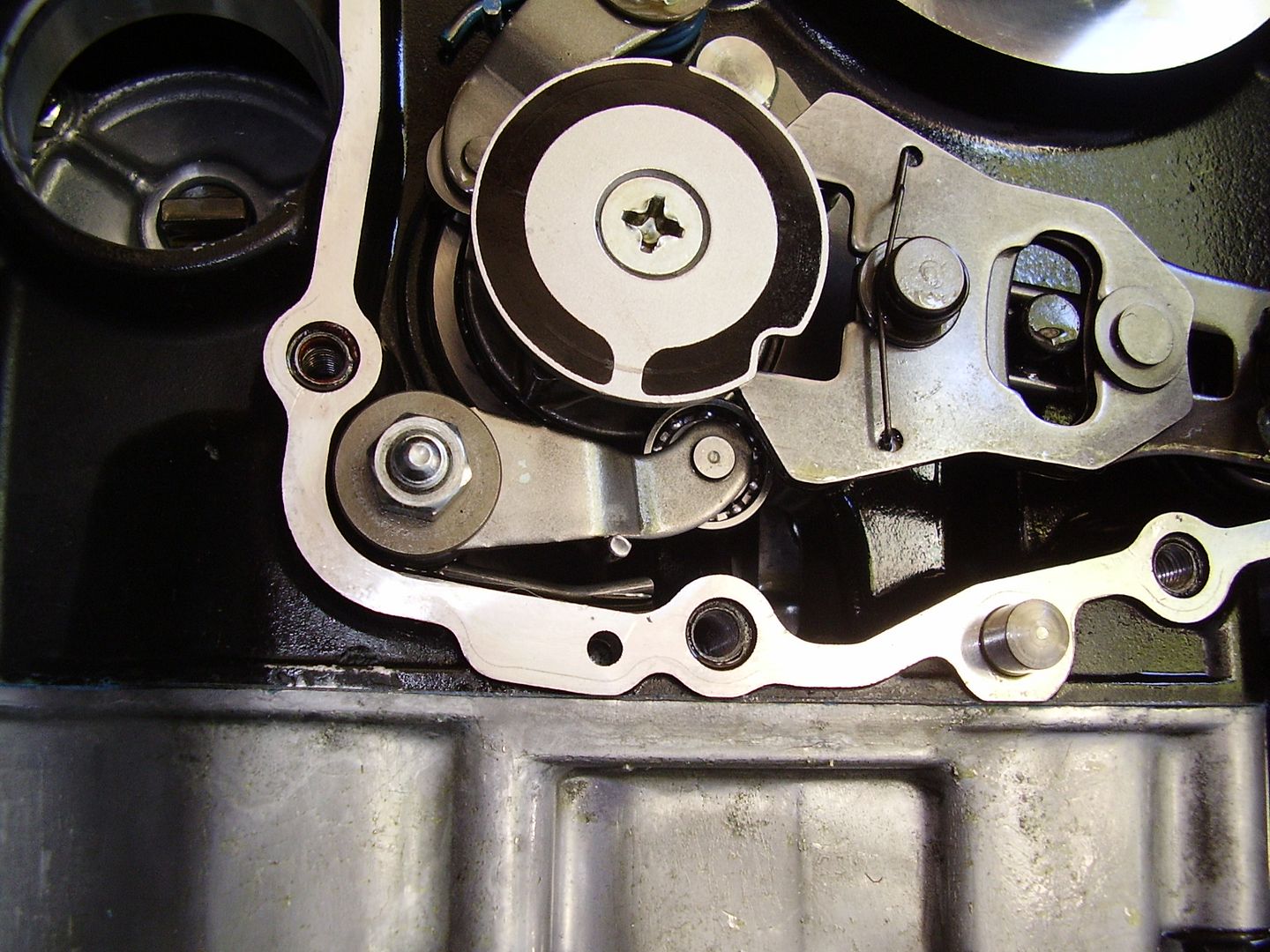

Yes, this can be done. I didn't believe it myself until Ken **** showed me how to do it. Not once but many times. It is just a matter of technique. But that didn't keep me from removing the pesky automatic neutral finder when I had the transmission out for another project:

With perfect results I might add.

Dan

Interesting D

I'm a bit surprised.... but not amazed, :great:

Thanks for showing that pic also...

I don't call "ball" feature a neutral "finder" tho, I call it an "upshift lockout" mechanism...

Now for the million dollar question....

Can anyone explain why it exists, and why it has been a part of every Kaw tranny since the early 70' s, or even before?

MAN OF BLUES said:Interesting D

I'm a bit surprised.... but not amazed, :great:

Thanks for showing that pic also...

I don't call "ball" feature a neutral "finder" tho, I call it an "upshift lockout" mechanism...

Now for the million dollar question....

Can anyone explain why it exists, and why it has been a part of every Kaw tranny since the early 70' s, or even before?

As far as I can recall, there were some bikes that were difficult to get into neutral at a stop with the engine running and in first (or second). It would just jump back and forth, very frustrating. I experienced this on several Japanese motorcycles from the 60s, 70, and 80s. I think Kawasaki came up with this as an answer.

IMO, the cure for this had to do with the neutral and gear arm detent springs as well as much higher quality clutch designs. When I was building the ZGRX, I strengthened both springs, removed the 3 balls shown there and never had a single issue with finding neutral at a stop in whatever gear I was in (1st or 2nd). It also did not hamper up or down shifting. Another benefit was very positive indexing while shifting, which was one of the goals of the Factory Pro ball bearing shift arm I also installed (with a stronger spring):

In the stock setup, the neutral index arm spring was slightly weaker than the gear index arm spring (I know, because I accidentally installed them backwards during the first build, they only differed visually by being painted different colors). The Factory Pro kit included a stronger gear arm spring so I moved the stock gear arm spring over to the nuetral arm. Shazam, perfect shifting.

Also, back in the day (60s, 70s, 80s, etc.), the wet clutches on Japanese bikes were not all that great. They would not completely release, especially when cold and they would often chatter near full engagement. This may have been an incentive for Kawasaki to invent the neutral finder.

Dan

Thanks Dan

I'm waiting for someone to send me the pictures I had,.that would actually explain visually the reason for the balls....

I looked on all 3 computers I have running, and can't find the pics, and thought I had them up on photobuttkit, but was wrong..

As soon as I get them I'll start another thread about this, and place a link here to direct to it...

I'm waiting for someone to send me the pictures I had,.that would actually explain visually the reason for the balls....

I looked on all 3 computers I have running, and can't find the pics, and thought I had them up on photobuttkit, but was wrong..

As soon as I get them I'll start another thread about this, and place a link here to direct to it...

Ok

The lockout is located in this section....

For future use...

http://forum.cog-online.org/concours-c10-zg1000-general-chat-and-tech/tips-tricks-a-few-important-warnings-and-other-valuble-threads-indexed-here/

The lockout is located in this section....

For future use...

http://forum.cog-online.org/concours-c10-zg1000-general-chat-and-tech/tips-tricks-a-few-important-warnings-and-other-valuble-threads-indexed-here/

dimmwitt89@hotmail.com

Mini Bike

Tjnoma99 said:I'm going to attempt my first valve adjustment this weekend. A few questions. Other than a head gasket, what other gaskets should I replace while I'm in there? I saw a reed valve block of kit from Murph. Is it worth it to do?

Something that I ran into when doing my first valve adjustment, involved getting the valve cover seal/gasket to stay in the groove along the top of the valve cover, especially in the front. A piece of plastic that helps direct heat around the radiator stuck back just enough, that it kept pushing the gasket into the engine. Before you're ready to carefully maneuver the valve cover between the frame and the engine, reach up with your thumb, and make sure the black plastic shield is pushed forward as far as it will move. Then, when you put the valve cover back on, I took a flashlight and inspection mirror to make sure the gasket/seal is still in the groove before putting on the valve cover bolts.

Another suggestion came from Steve: I highly recommend buying and using two feeler gauges, for setting both valves (exhaust-exhaust intake-intake) per cylinder at the same time. Trying to jump between both with a single feeler gauge is a PITA.

Good luck!

The Link contained herein is no longer working. Error 404You can do the valve adjustment without removing the pickup coil cover so you won't need that gasket. Just use the timing marks on the cams or have the lobes pointing up. With the plugs out, you can spin the engine with the trans in 6th using the rear wheel or just bump the starter. If you haven't found it already in the Tech Pages, here's the link for valve adjustment:

http://www.cog-online.org/clubportal/clubstatic.cfm?clubID=1328&pubmenuoptID=29654

When putting it back together, be gentle on the valve cover bolts: 87 in/lb

I concur with your signature line 1000%. Ad sponsors will pay you quite enough to keep the site FREE for all with the minor inconvenience of having to close an ad tag. No big deal to me. I host a different brand site and I charge NO ONE, yet, members feel the need to DONATE for all the wisdom and helpful members posts. I do accept Donation there, but I do NOT solicit them. I actually try and dissuade them. Some folks INSIST. Well if you INSIST.I've done two valve jobs now, and the second one was way easier with some experience.

I would highly suggest going ahead and replacing the t-stat, oring, and rear coolant long rings while you're in there. Not only is it good preventive maintenance, getting the cover back on is a breeze.

I use indian head on the cover side. Apply, wait a bit to let it cure, then put the gasket on and let it sit 24 hours. If you have the tstat and coolant log off, you can approach from behind. Like many have said, just a little RTV in the half moon wells, and a little on the corners. I went sparingly on that part as well. First attempt at mounting the cover was successful. Much better than the 3 times it took on my 06 to get a good seal without a leak. I hadn't taken the tstat off on that guy, so it's not a surprise.