My tyre mechanic did it again, properly broke the sensor case, circuit board and valve stem! These are the 1st generation sensors with a battery that is replaceable and I wanted to keep these alive rather than fit 2nd gen sensors.

As you can see, the positive terminal is broken away on the board, I've re-engineered a solder point for the positive rail on the board.

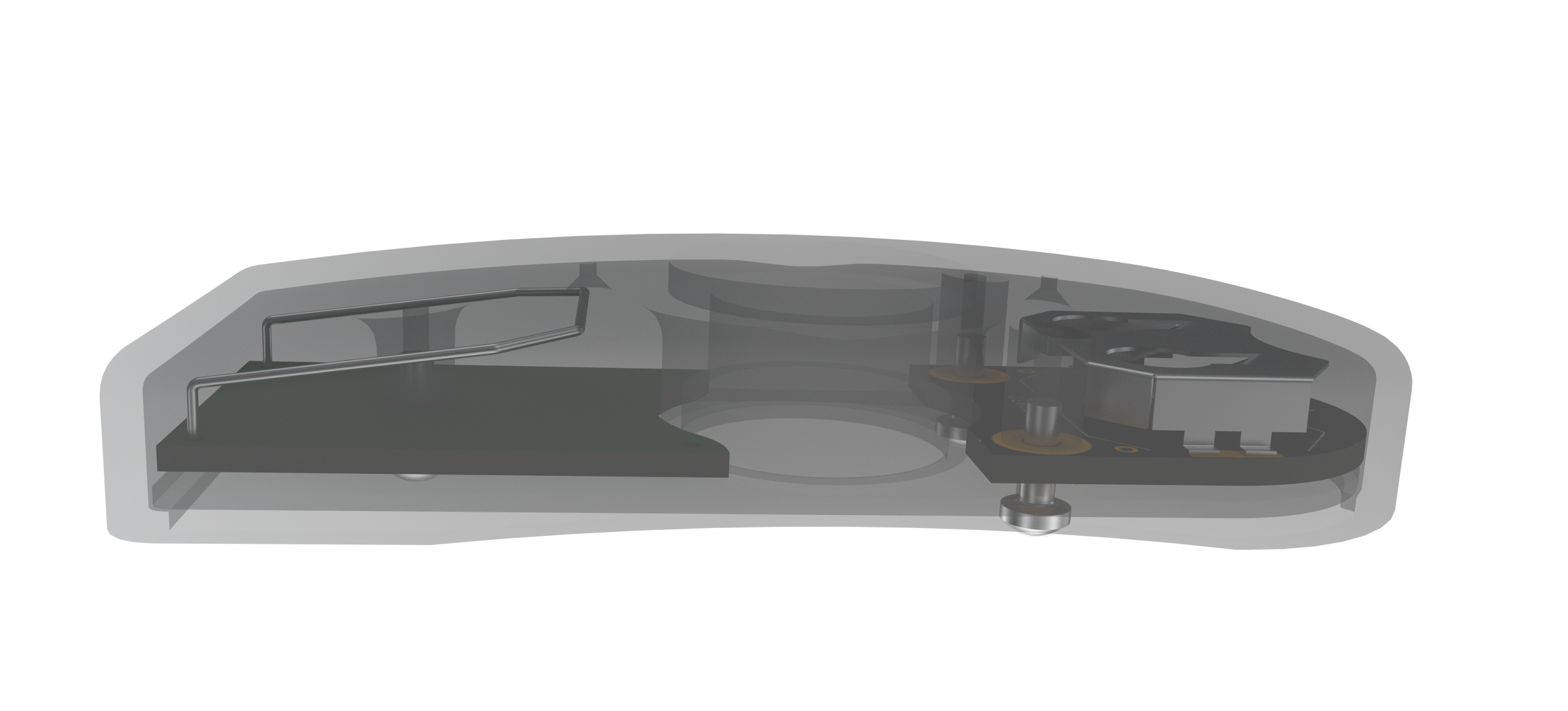

I'm posting my modifications to the sensor which I have just completed. This comprises of a replacement battery holder that does not require soldering the battery, and a robust nylon enclosure closely matching the shape of the original.

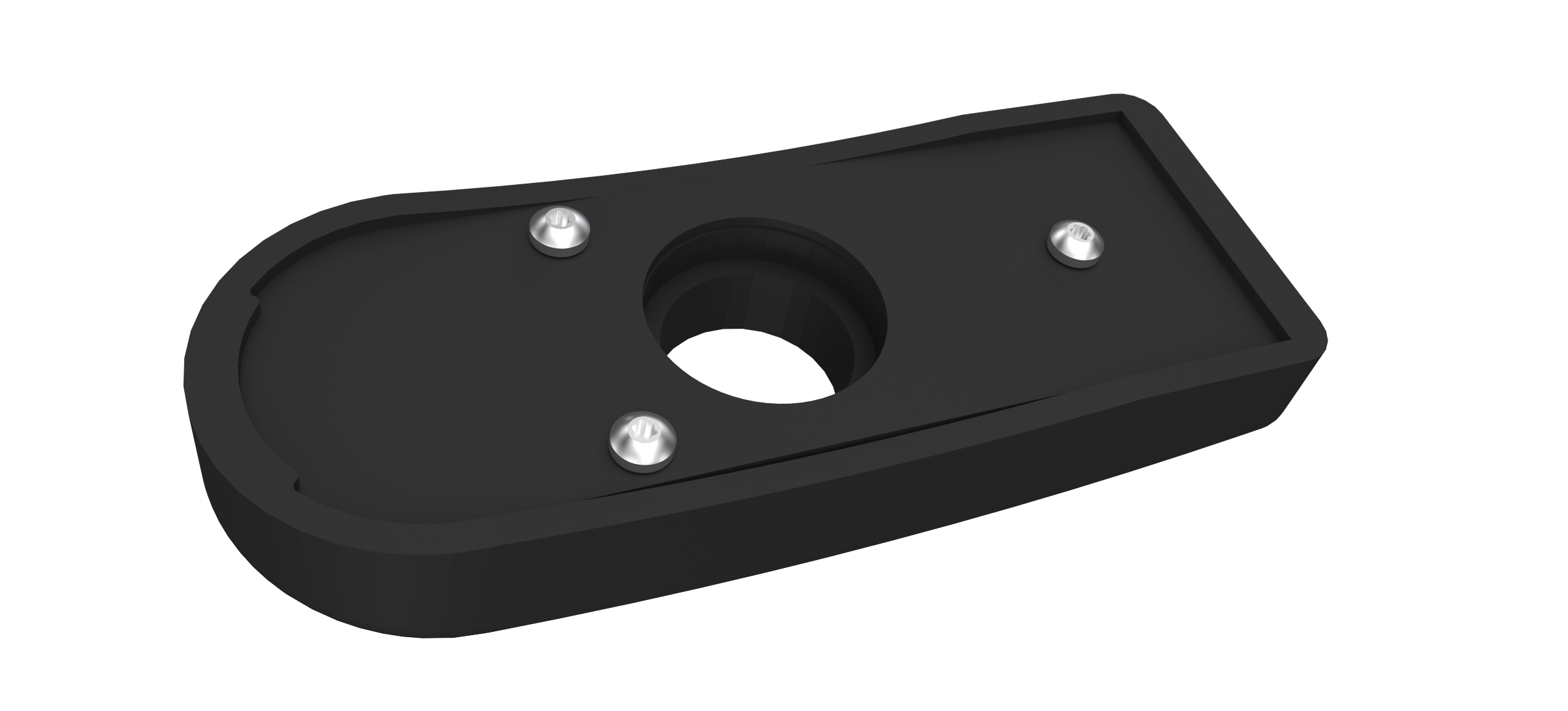

The width of the enclosure has been increased from 23.6mm to 28.3mm to accommodate the size of the battery board and also to provide a 2mm wall thickness for added strength.

It's designed as a repair or an upgrade to the OEM sensor module, where the original board, if it's still functional, is removed and the battery terminals on the board are de soldered and replaced with 24AWG flexible silicone wire with ring terminals to attach to the battery holder. The enclosure lid is held down by screws that also anchor the two circuit boards and complete the battery circuit. The original sensor standoff and spring are required for re-fitting to the wheel.

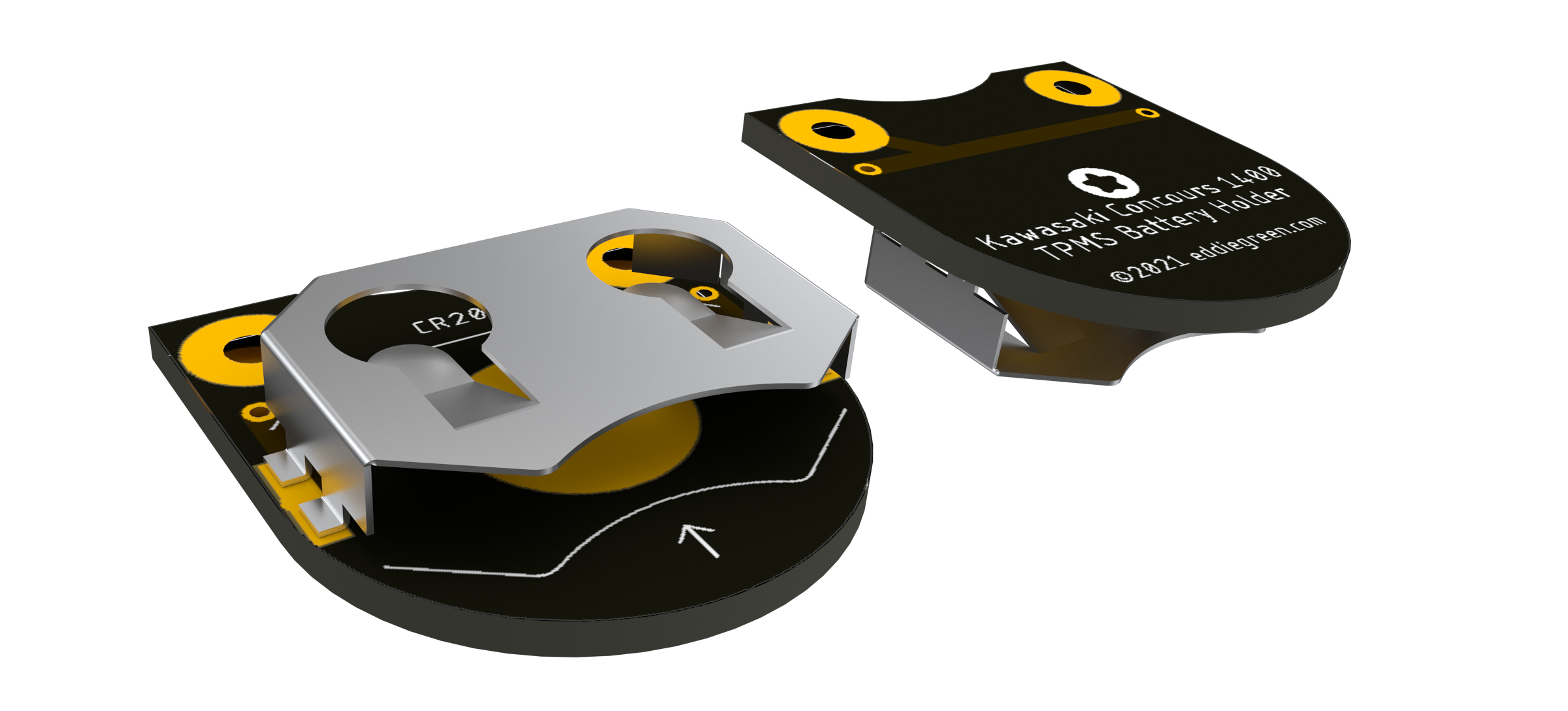

This is the battery holder:

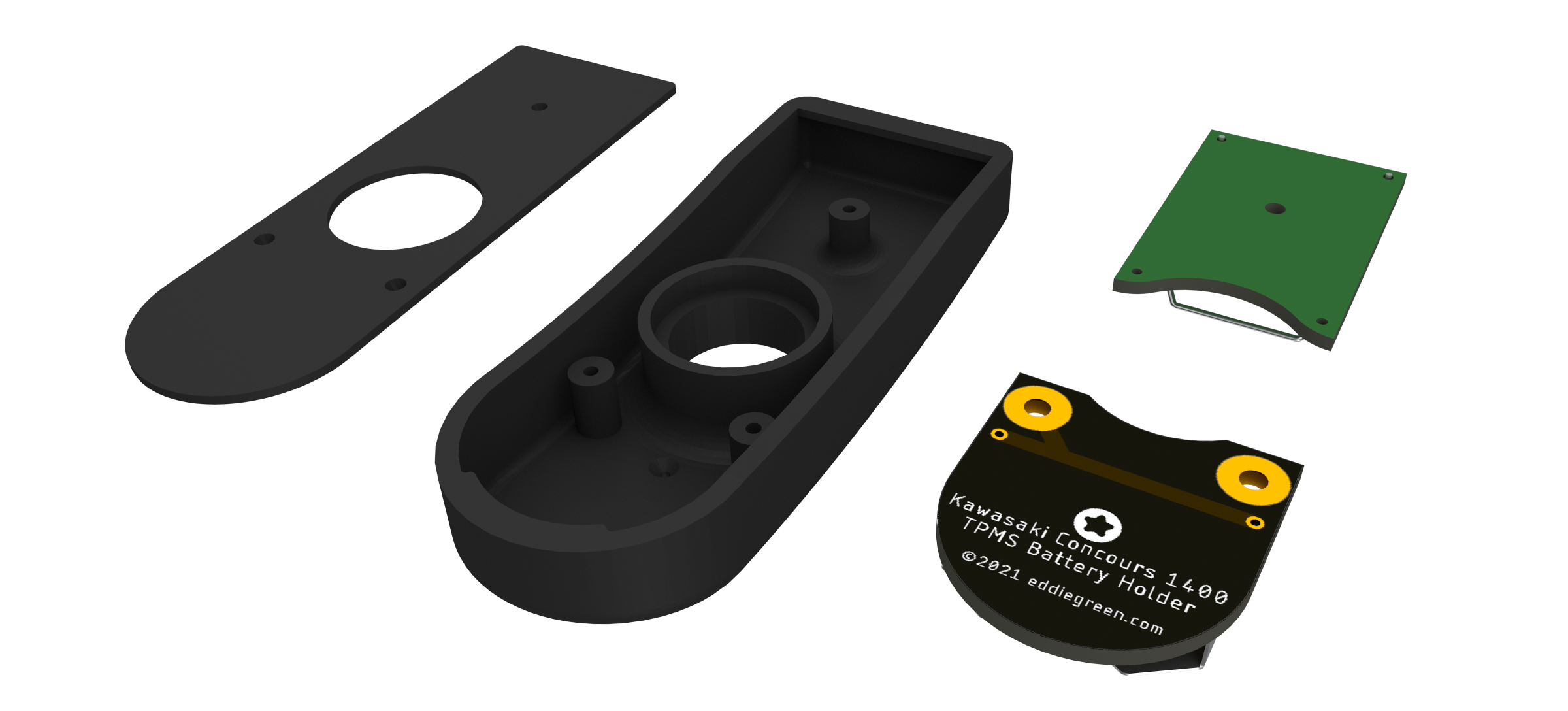

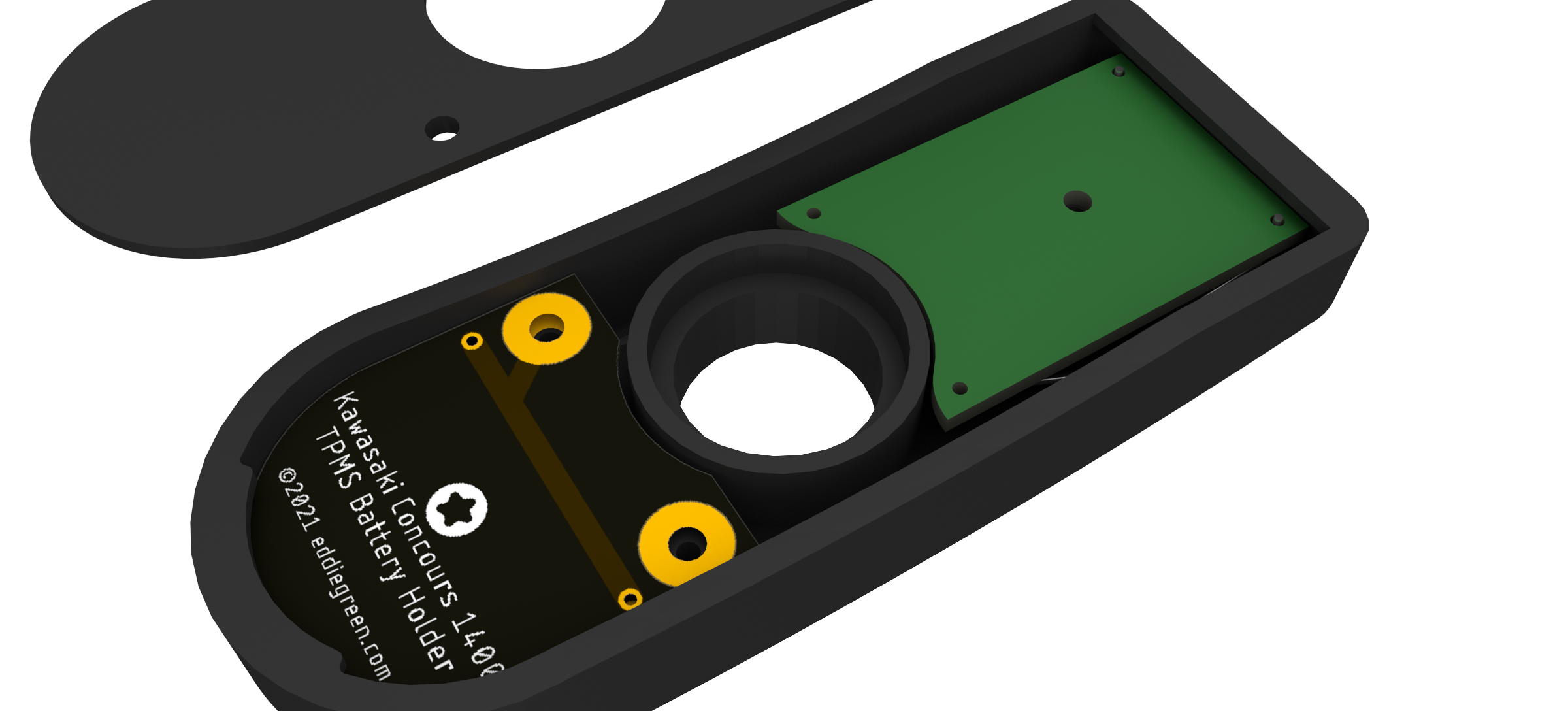

The following images show components and the assembly detail:

The components required are in production at the moment. I've ordered enough 3D prints and circuit boards to make six units so will have spare sets to make available to people who would like to perform the upgrade.

I'm also waiting on 8.3mm right-angled valve stems which will complete the project.

I'd be interested to know whether it is worthwhile producing these as a kit, so let me know your views.

As you can see, the positive terminal is broken away on the board, I've re-engineered a solder point for the positive rail on the board.

I'm posting my modifications to the sensor which I have just completed. This comprises of a replacement battery holder that does not require soldering the battery, and a robust nylon enclosure closely matching the shape of the original.

The width of the enclosure has been increased from 23.6mm to 28.3mm to accommodate the size of the battery board and also to provide a 2mm wall thickness for added strength.

It's designed as a repair or an upgrade to the OEM sensor module, where the original board, if it's still functional, is removed and the battery terminals on the board are de soldered and replaced with 24AWG flexible silicone wire with ring terminals to attach to the battery holder. The enclosure lid is held down by screws that also anchor the two circuit boards and complete the battery circuit. The original sensor standoff and spring are required for re-fitting to the wheel.

This is the battery holder:

The following images show components and the assembly detail:

The components required are in production at the moment. I've ordered enough 3D prints and circuit boards to make six units so will have spare sets to make available to people who would like to perform the upgrade.

I'm also waiting on 8.3mm right-angled valve stems which will complete the project.

I'd be interested to know whether it is worthwhile producing these as a kit, so let me know your views.