I wanted to share some tips for doing the Valve Clearance Adjustment on a Gen- 2 C-14. I hope others will chime in with their own tips. This is not intended to be an expert opinion or a step by step guide, but rather the intent is to help out a newbie that might have the same question and concerns that I had along the way. I'll also point to differences between the Gen 1 videos and the Gen 2 model.

Between the Service Manual, Fred's Video's and posts, and posts from Man of Blues, BDF, and Mad River Marc, all of the information is there to do the job right. These tips will hopefully pull many of those things together so you don't need to search them out.

Should I even start the Job?

First off, I was telling myself it was ok to wait until 25,000 miles to check the valves, and not the US/CA 15,000 mile interval. Many posts say that is ok. I checked with two local dealers, and aside from realizing the job was expensive after asking the price, I got two different answers. One said ok to wait, the other said you will want to check them, since they have come across tight valves. I had 13,750 miles on the bike, and plan to pile up miles this summer, and I decided to do the job myself over winter and not during prime riding season. I’m cheap, so the money savings was appealing. I also had a mental image of my C-14 scattered across a Motorcycle shop for days and getting unknown results. In the end, I felt confident in my abilities and decided to go for it. I’m not a motorcycle mechanic by any means, but over the years, I would always did my Periodic cycle and car/truck maintenance (4th Bike) and I do not hesitate to replace an alternator, water pump, etc on a car. But removing the cams after 1½ years? Are you kidding me; that is surely beyond my skills right? I have the tools, this Forum, and Fred’s videos. Turns out that is all you need.

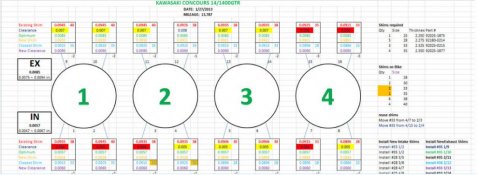

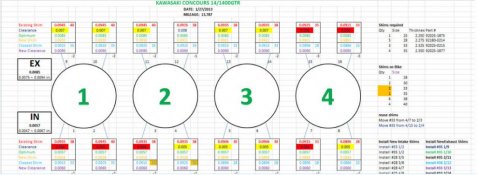

I found 2 exhaust valves and 4 intake valves out of spec and tight, and the remaining 10 valves were on the tight side of the spec. They are now loosened back to 0.009 on the Exhaust, and 0.006 on the Intakes. In my opinion, checking and adjusting them at the early interval was a good idea. Others will dispute that I’m sure.

---CONTINUED----

Between the Service Manual, Fred's Video's and posts, and posts from Man of Blues, BDF, and Mad River Marc, all of the information is there to do the job right. These tips will hopefully pull many of those things together so you don't need to search them out.

Should I even start the Job?

First off, I was telling myself it was ok to wait until 25,000 miles to check the valves, and not the US/CA 15,000 mile interval. Many posts say that is ok. I checked with two local dealers, and aside from realizing the job was expensive after asking the price, I got two different answers. One said ok to wait, the other said you will want to check them, since they have come across tight valves. I had 13,750 miles on the bike, and plan to pile up miles this summer, and I decided to do the job myself over winter and not during prime riding season. I’m cheap, so the money savings was appealing. I also had a mental image of my C-14 scattered across a Motorcycle shop for days and getting unknown results. In the end, I felt confident in my abilities and decided to go for it. I’m not a motorcycle mechanic by any means, but over the years, I would always did my Periodic cycle and car/truck maintenance (4th Bike) and I do not hesitate to replace an alternator, water pump, etc on a car. But removing the cams after 1½ years? Are you kidding me; that is surely beyond my skills right? I have the tools, this Forum, and Fred’s videos. Turns out that is all you need.

I found 2 exhaust valves and 4 intake valves out of spec and tight, and the remaining 10 valves were on the tight side of the spec. They are now loosened back to 0.009 on the Exhaust, and 0.006 on the Intakes. In my opinion, checking and adjusting them at the early interval was a good idea. Others will dispute that I’m sure.

---CONTINUED----

Last edited: